MINING ENGINEERING

HYDRAULIC STRUCTURES

LANDFILLS

BUILDING CONSTRUCTION

PUBLIC WORKS

MINING ENGINEERING DRAINTUBE FT

Use

To drain dry tailings of mining waste materials, DRAINTUBE® FT is installed in the dike to help decrease the level of the perched water table and improve the overall stability of the structure.

To increase the capacity of dikes in terms of mine tailings, the dams built using the upstream method are often preferred over alternative methods, as they as more economical. The limitation of this method lies in the possible rise in groundwater within the structure, causing stability issues. Safety can be greatly improved by the use of DRAINTUBE® FT between rising episodes.

Another key issue with mining operations is the management of sands and their storage in dikes. The sand saturation level and slopes are controlled, and depend on the nature, permeability, internal cohesion and saturation level of sand. DRAINTUBE® FT is used on various levels during the construction of the dike, between two soil layers, to accelerate soil desaturation and therefore increase the safety factor on the overall stability of the structure.

Benefits

- Effective drainage under heavy stress

- Reduced risk of dike failure

- Better use of tailings to build stable slopes

- Optimisation of existing deposition areas

- Savings in granular material

- Replacement of trenches with a system connecting the mini-drains to the collector drain : Quick Connect System

- Ease of installation with a single product to unroll

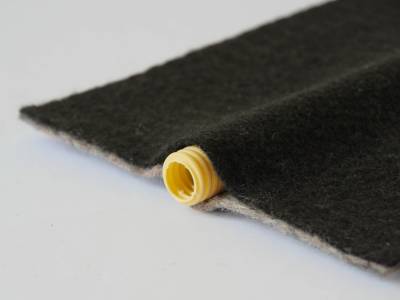

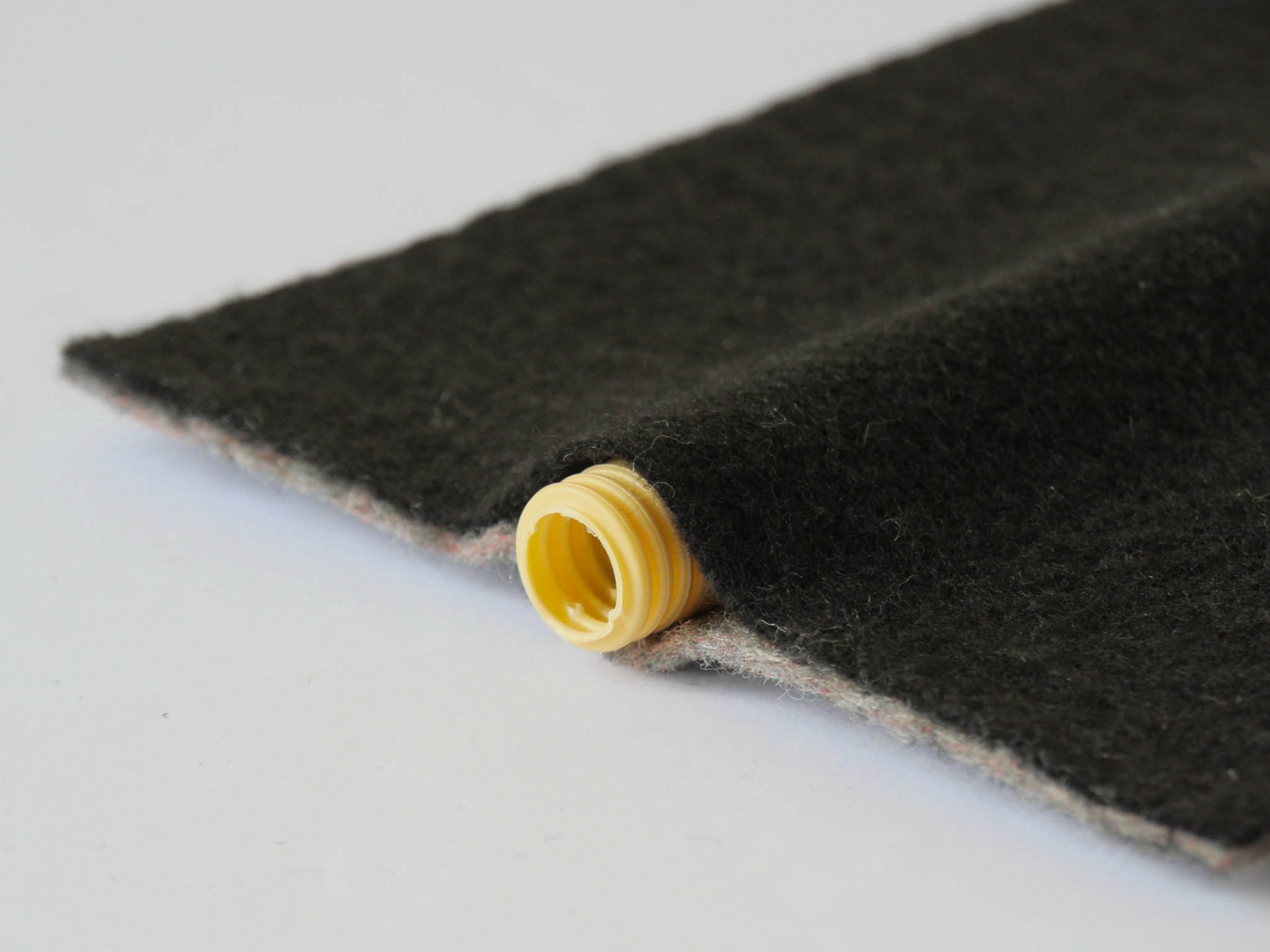

Features

Drainage

Drainage

Filtration

Filtration

Characteristics

- Polypropylene geocomposite

- Roll width : 3.90 m

- Roll length : 50 m

- 3 diameters of perforated mini-drains : 16 mm, 20 mm and 25 mm

- 4 possible distances between mini-drains : 200 cm, 100 cm, 50 cm and 25 cm